Home>> Roller Bearing>>Roller Bearing >> Spherical Roller Bearings

Spherical Roller Bearings

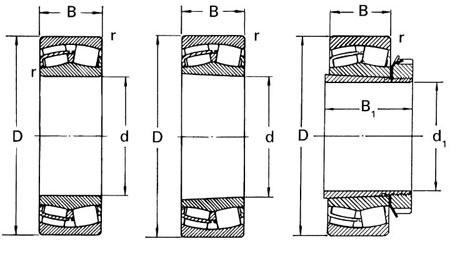

Spherical Roller Bearingshave two raceways on inner ring. They are the one with spherical raceway on outer ring and spherical rollers. Since the center of the raceway on the outer ring is the same as the center of the whole bearing arrangement, so these bearings are self-aligned and automatically adjust the eccentricity arose from the error of mounting bearings in housings or from the bending of the shafts. The bearings can normally run when the acute angle between the centric lines of outer ring and inner ring ranges within 1°~2.5°. The bearings can accommodate radial load and axial load in double directions. The especial radial load carrying capability makes these bearing suitable for heavy load and shock load carrying.

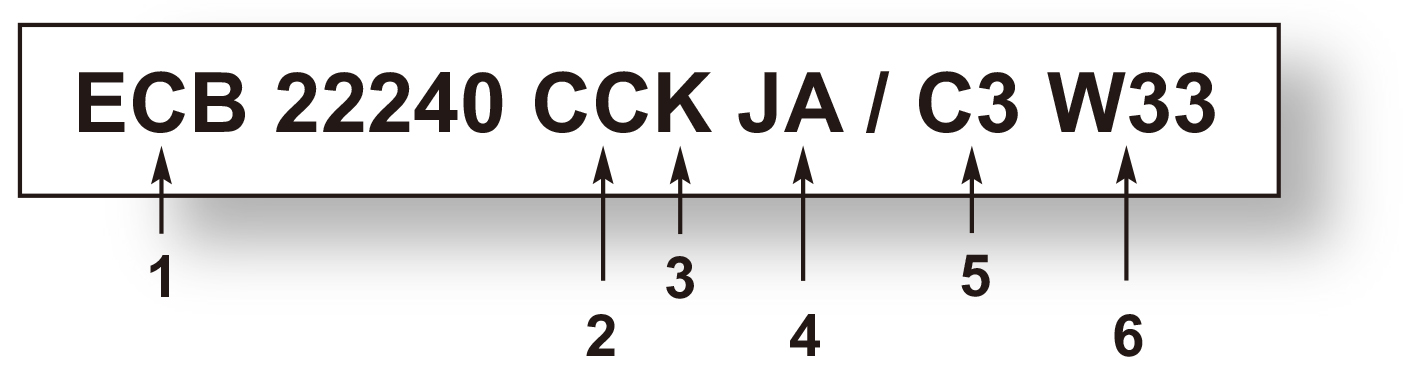

1. Prefixes | 4. Cage Designation/Seals | W22 | Special reduced outside | ||

ECB | Air melt carburized steel, inner | 2CS | Nitrile rubber seals on both | diameter tolerance for outer ring | |

ring only | sides, bearing filled with | W26 | Six lubrication holes in inner | ||

BS2 | Double row spherical roller | medium temp. extreme | ring | ||

bearing with special dimensions | pressure grease | W31 | Bearing inspected to special | ||

for seals | 2CS2* | Fluoroelastomer rubber | quality requirements | ||

2. Internal Design | seals on both sides, filled with | W33 | Groove and 3 oil holes in outer | ||

CA | One-piece machined brass | hi-temp grease* | ring | ||

cage of the double-pronged | 2CS5 | Hydrogenated Acrylonitrile | W33X | Lubrication groove and six | |

type, retaining flanges on the | (HNBR) seals on both sides | holes in outer ring | |||

inner ring and guide ring | filled with 70-100% of Polyurea | W4 | Hi point of eccentricity | ||

centred on the inner ring. | based hi-temperature grease | marked on inner ring or | |||

CAC | Same as CA but improved | F | Machined steel cage, ring | sleeve | |

raceway geometry | guided | W502 | Combination of W22 and W33 | ||

CAFA | Same as CA but with a | J | Pressed steel cage | W509 | W26 + W31 + W33 |

machined steel cage. | JA | Hardened steel cage, ring | W513 | W26 + W33 | |

CC | Two, window-type steel cages, | guided | HA1 | Case hardened outer and inner | |

flangeless inner ring and guide | MA | Machined brass cage outer ring | rings | ||

ring centred on the inner ring | guided | HA3 | Case hardened inner rings (As | ||

E | d < 65mm, Two window-type | M2 | Machined brass roller guided | ECB prefix) | |

steel cages, flangeless inner | cage no guide ring (Vibrating | VA405 | Vibrating screen specification | ||

ring and guide centred on the | screens) | VA406 | As VA405 with PTFE coated | ||

inner ring. When d >65 mm as | Y | Pressed brass cage, ring | bore | ||

above but guide ring centred on | guided | VE552 (E) | Three equally spaced | ||

the cages | 5. Clearance/Tolerance | threaded holes in face of | |||

ECA | One-piece machined brass | C1 | Clearance < C2 | outer ring for hoisting tackle, | |

cage of the double-pronged | C2 | Clearance < Normal | (E) indicates appropriate lifting | ||

type, retaining flanges on the | CN | Normal (no symbol) | eyes supplied | ||

inner ring, guide ring centred on | C3 | Clearance >Normal | VE553(E) | As VE552 but on both | |

the inner ring and reinforced | C4 | Clearance >C3 | side faces. | ||

roller complement | C08 | Reduce runout on both | VA751/VA759Both printing press/ | ||

ECAC | As ECA but with improved | inner and outer rings to | coater specifications | ||

raceway geometry | ISO P5 (RBEC 5) | VT143 | Extreme pressure grease | ||

ECAF | As ECA but with a machined | VQ 424 | Closer tolerances than C08 | W64 | Solid oil filling |

steel cage | 6. Features | W77 | Plugged W33 holes | ||

3. Bore types | W | No relubrication feature | |||

- | Cylindrical bore no symbol | on E style bearings | |||

K | 1:12 tapered bore | ||||

K30 | 1:30 tapered bore | ||||